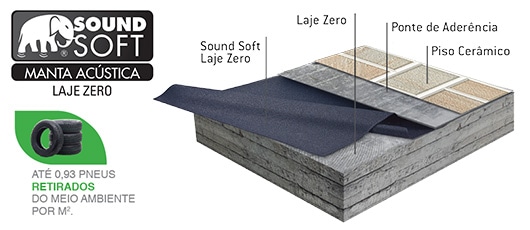

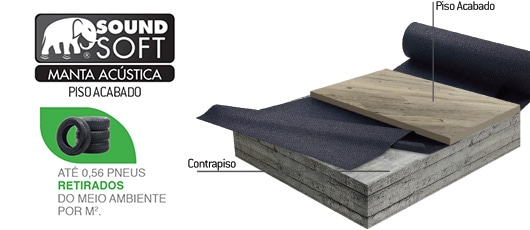

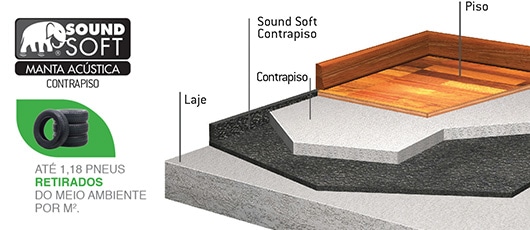

ACOUSTIC MATS

SOUND SOFT UNDER SCREEDS

WAVE SOUND SOFT

The Wave Sound Soft is new in the Brazilian market. A pioneer in the manufacturing of this type of underlayment, Aubicon follows worldwide trends regarding impact noise absortion.

The underlayment shall be used with the concept of floating flooring and meets the projects with greater demands of acoustic treatment. Due to its specific geometry, the material reduces contact of the anti-vibrating base with the rest of the structure, besides ensuring high dampening of the system. It offers high performance and high compression resistance.

Advantages

Specific geometry

Durability

Ideal for areas with heavy equipment

May be used in wet areas

CHARACTERISTICS

COMPOSITION Pre-fabricated recycled tire granule mat binded with polyurethane

THICKNESS: 6/3, 8/4, 10/5 and 17/8mm. Others on demand

DENSITIES: 600 and 750 Kg/m3

MEETS VUP: Higher level (over 20 years)INSTALLATION

- Before applying the underlayment, the slab must be clean;

- Remove loose material, depressions or bumps and fill the holes with dry mass;

- Remove excessive mass, especially in the point between the slab and masonry.

- With a stylet, cut the mat leaving 1 cm in masonry for 3 and 5 mm underlayments. For 8 and 10 mm underlayment, cut them in the measurement of the room;

- Calculate an overlap of 5 cm between materials for 3 and 5 mm mats. For 8 and 10 mm mats, support one beside the other and apply silver tape to all mends.

- Support the underlayment onto the slab and later the footer strips behind it. Do that for the perimeter of the room;

- The footer shall separate areas with acoustic flooring from areas without acoustic flooring;

- Holes in the mats shall be filled with a piece of the same material;

- Tubing shall pass over the underlayment and there shall be 2cm of mass between the tubing and the surface.

- Follow the instructions of the Aubicon Screed technical manual;

- One may add microfiber to the flooring and use metallic screens in the re-entry corners;

- Trace with ¼ (cement/sand) with fluffy texture and average thickness of 4 cm;

- Compact the flooring with a socket/compacter and apply a wet cure;;

- Cut excess from the footers at the height of the final cover;

- In case the underlayment is used in high load areas, verify Aubicon technical manual.

****************

DURABILITY

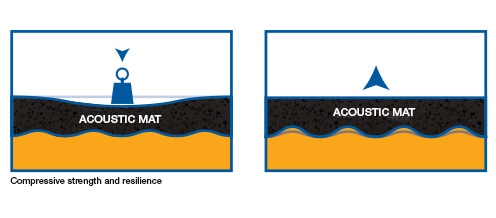

Sound Soft Acoustic Underlayments have the advantage of presenting acoustic comfort and durability for the useful life of the work. This product has low compressibility and basically returns to its original thickness even when submitted to loads of up to 20 kN/m2. It is permanently elastic and possesses a high resilience capacity, allowing for maximum loads of 2500 kg/m2 without affecting performance.

The compression fluency test analyses material behavior in the long term when compressed by a specific weight. There was a loss of 7% in thickness under a 10 kPa load. This result ensures that the flooring and applied cover do not suffer damages during the useful life of the work due to system movements. The material was also tested in order to verify resistance to mediums with high alkaline content such as concrete. One may observe that the product is alkali-resistant and, therefore, inert to alkaline attack.

The material was also tested to identify their resistance to high alkalinity media content such as concrete. It can be seen that the product is alkali-resistant and hence an inert material to alkaline attack.

SYSTEM VUP(YEARS) MINIMUM INTERMEDIATE SUPERIOR Inner flooring ≥ 13 ≥ 17 ≥ 20 NBR 15575 – VUP (Project useful life).

RESULTS TABLE

The following are the international reference results of lab tests for each thickness of the Wave Sound Soft acoustic mat.

| Thickness | ΔLw |

| 6/3 | 22 dB |

| 8/4 | 24 dB |

| 10/5 | 25 dB |

| 17/8 | 27 dB |

© 2019 | Aubicon | All Rights Reserved |

© 2019 | Aubicon | All Rights Reserved |