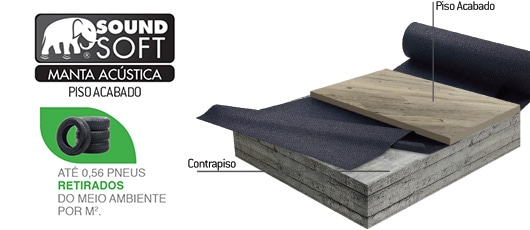

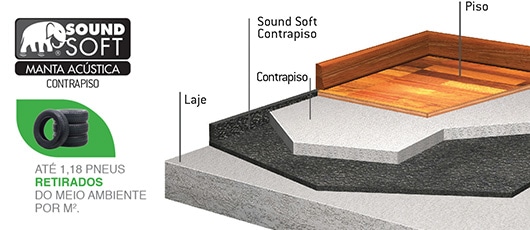

ACOUSTIC MATS

UNDER FLOOR COVERING

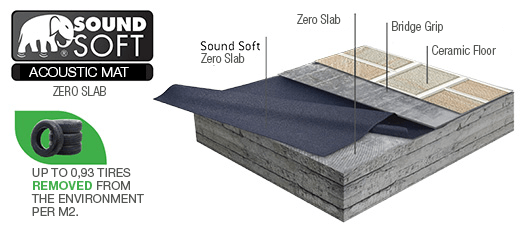

Zero SlabSound Soft

A pre-fabricated underlayment with guaranteed constant thickness and density. Ideal for projects that does not attend minimum levels required by NBR 15575-3 regarding impact noise and that have no possibility to use a regular screed layer in their construction method. The underlayment is glued with a specific cement glue developed for this product usage.

Advantages

Guaranteed constant thickness and density

Rationalized and easily executed system

Meets the 15575-3 standard without great structural changes

May be used in Retrofit work

CHARACTERISTICS

COMPOSITION: Pre-fabricated recycled tire granule mat binded with polyurethane

THICKNESS: 2,3 and 5mm. others on demand

DENSITIES: 750 Kg/m3

Meets VUP: higher level (over 20 years)INSTALLATION

- Before applying the underlayment, the base shall be clean and plain;

- Remove overlapping parts with the help of a chisel and sweep the place to remove dust and solid residue.

- With a stylet, cut the underlayment to the measurements of the room;

- Underlayment shall be glued from the top, without spacing;

- Any hole in the underlayment shall be filled with a piece of the same material.

- In a recipient with water, add Cement Glue Zero Slab and use a mixing helix coupled with a drill;

- Apply Cement Glue onto the base with a dented 3 mm straightener to form strings;

- Apply the underlayment and press it with the smooth side of the straightener until it is in full contact with the base.

- 24 hours after the fixation of the acoustic underlayment, the finish flooring may be executed;

- For better running results of the system, perform an adherence bridge before the application of the final cover. Check the Aubicon manual;

- The application of ceramic flooring and stones on the adherence bridge shall be made according to recommendations of manufacturers of these covers.

****************

DURABILITY

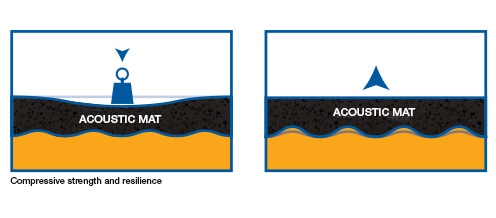

Sound Soft Acoustic Underlayments have the advantage of presenting acoustic comfort and durability for the useful life of the work. This product has low compressibility and basically returns to its original thickness even when submitted to loads of up to 20 kN/m2. It is permanently elastic and possesses a high resilience capacity, allowing for maximum loads of 2500 kg/m2 without affecting performance.

The compression fluency test analyses material behavior in the long term when compressed by a specific weight. There was a loss of 7% in thickness under a 10 kPa load. This result ensures that the flooring and applied cover do not suffer damages during the useful life of the work due to system movements. The material was also tested in order to verify resistance to mediums with high alkaline content such as concrete. One may observe that the product is alkali-resistant and, therefore, inert to alkaline attack.

The material was also tested to identify their resistance to high alkalinity media content such as concrete. It can be seen that the product is alkali-resistant and hence an inert material to alkaline attack.

SYSTEM VUP(YEARS) MINIMUM INTERMEDIATE SUPERIOR Inner flooring ≥ 13 ≥ 17 ≥ 20 NBR 15575 – VUP (Project useful life).

Technicalreport

In a test performed with the acoustic underlayment Sound Soft Zero Slab 2mm, the impact sound pressure level was measured at 76 dB, thus framing the work that previously did not meet the minimum levels required by NBR 15575-3.

| Frequency (HZ) | Without flooring L’nT(third of an octave) dB | L’nT (third of an octave) dB |

| 50 | – | – |

| 63 | – | – |

| 80 | – | – |

| 100 | 65,8 | 61,2 |

| 125 | 67,5 | 62,8 |

| 160 | 75,9 | 71,6 |

| 200 | 71,6 | 69,4 |

| 250 | 74,3 | 71,8 |

| 315 | 75,4 | 72,8 |

| 400 | 76,1 | 72,6 |

| 500 | 77,1 | 71,3 |

| 630 | 78,3 | 72,2 |

| 800 | 78,0 | 70,0 |

| 1000 | 77,7 | 66,8 |

| 1250 | 78,2 | 63,5 |

| 1600 | 78,6 | 60,1 |

| 2000 | 78,2 | 56,1 |

| 2500 | 78,1 | 51,5 |

| 3150 | 77,4 | 45,8 |

| 4000 | – | – |

| 5000 | – | – |

| L’nT,w Classification according to ISO 717-2 | 84 dB | 68 dB |

| *Acoustic Harmony – Report 13‐309A‐EIM. | ||

© 2019 | Aubicon | All Rights Reserved |

© 2019 | Aubicon | All Rights Reserved |